RFID High-Temperature Tags

High-Temperature RFID Tags are specifically engineered to withstand extreme industrial environments, where high heat, chemical exposure, and challenging conditions are part of daily operations. These tags maintain reliable performance even at temperatures reaching up to 230°C, ensuring continuous product identification and tracking throughout intense manufacturing processes. Designed with specialized materials, these tags provide durability, accuracy, and consistency in environments like automotive production, metal processing, and electronics manufacturing. Their rugged construction makes them ideal for metal surfaces, offering high resistance to heat, vibration, ultrasonic cleaning, and harsh chemical exposure

Key Features

Extreme Heat Resistance: Operates effectively in environments reaching up to 200°C with peak endurance of 230°C for one hour.

Durable Construction: Built with black-grey plastic and rated IP68 for maximum protection against dust and water.

Reliable Performance: Ensures consistent tracking through rigorous testing for temperature tolerance and performance stability.

Versatile Installation: Can be applied using rivets, screws, adhesive tape, or glue, making installation adaptable to various surfaces.

Technical Specifications

Operating Frequency: 902–928 MHz / 865–868 MHz (customizable).

Tag Type: Tag With Casing.

Read Range: UHF up to 8 to 10 meters.

Durability: IP68 (dust-tight and water-resistant).

Customization: Options for branding, and data capacity.

Technical Specifications

Dimensions and Weight:

46 × 46 × 7.5 mm (Customization Available)

Materials:

ABS Plastic

Frequency:

865-867 MHZ

Protocol:

EPC Class 1 Gen 2; ISO 18000-6C

Chip Type:

Alien Higgs-3/4,

Monza 4/4QT/5/R6/R6P, UCODE 7/8 Chip

Read distance:

Up to 8m to 10m

Data Retention:

Up to 10 Years

Operating Temperature:

-25°C to 95°C Peak Temp 230°C for one hour

Memory:

PC 96 bits (480 bits optional), user area 512 bits

Attachment:

rivets, screws, adhesive tape, or glue

Places of Application

Manufacturing:

Monitors clothing production and movement within factories.

Automotive Industry:

Tracks vehicles and parts through high-heat production lines.

Construction:

Ideal for tracking equipment and materials in high-temperature construction environments.

Supply Chain Management:

Enhance visibility and efficiency across the logistics process.

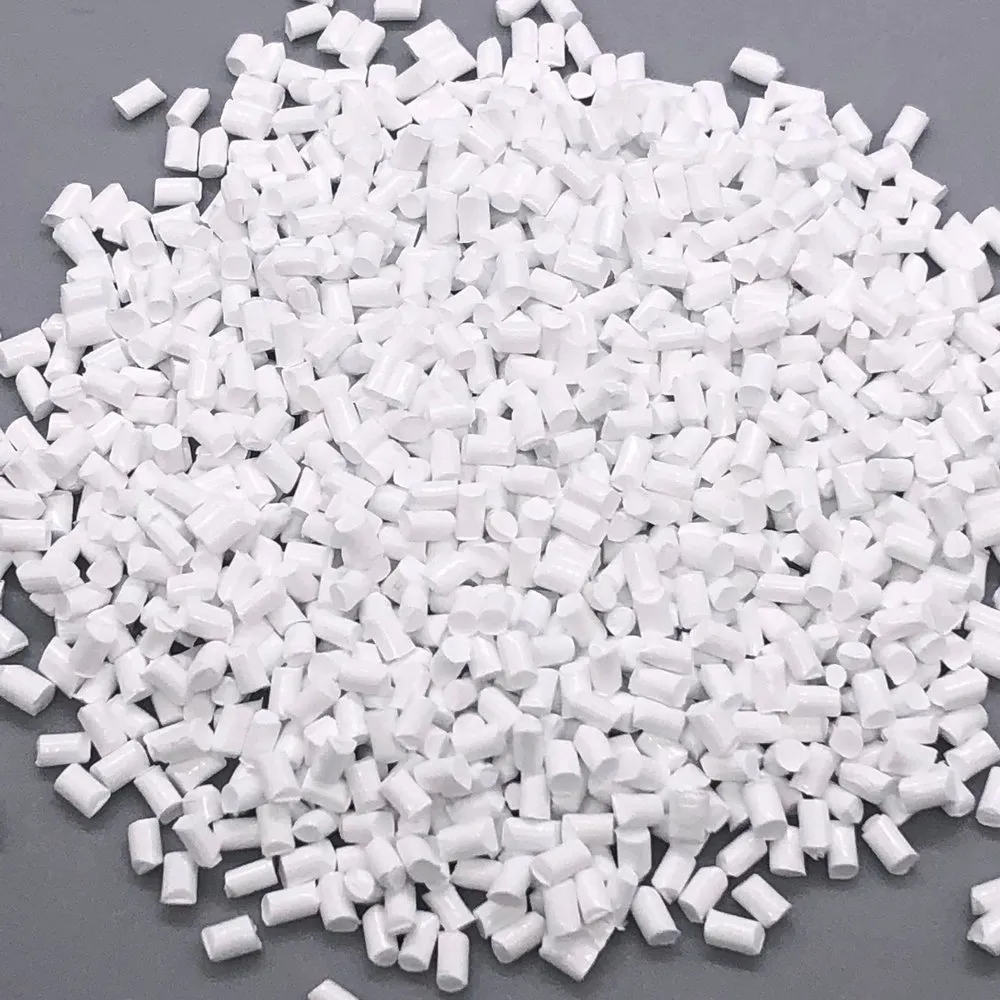

Types of Material

ABS

ABS (Acrylonitrile Butadiene Styrene) is a high-performance thermoplastic renowned for its exceptional durability and resistance to extreme conditions. It combines the strength and rigidity of acrylonitrile and styrene with the toughness of polybutadiene, resulting in a material that withstands prolonged exposure to high temperatures without warping or degrading. ABS offers remarkable impact strength, ensuring durability even in demanding industrial environments. Its chemical resistance protects against corrosion from oils, acids, and other harsh substances, making it ideal for use in rugged conditions. Lightweight yet sturdy, ABS provides long-term structural integrity, making it the perfect choice for high-temperature RFID tags.

Types of Detailing on Labels/Tags

Logo Printing

Enhance your brand visibility with custom logo printing available on both the front and back of the labels, ensuring a professional and recognizable design for all your products.

Sequential Numbering

Add unique sequential numbers on the label or release paper for accurate tracking, identification, and enhanced operational efficiency.

Encoding Data

Securely encode essential information directly onto the label, allowing for quick access and accurate tracking of product details, inventory, and more.