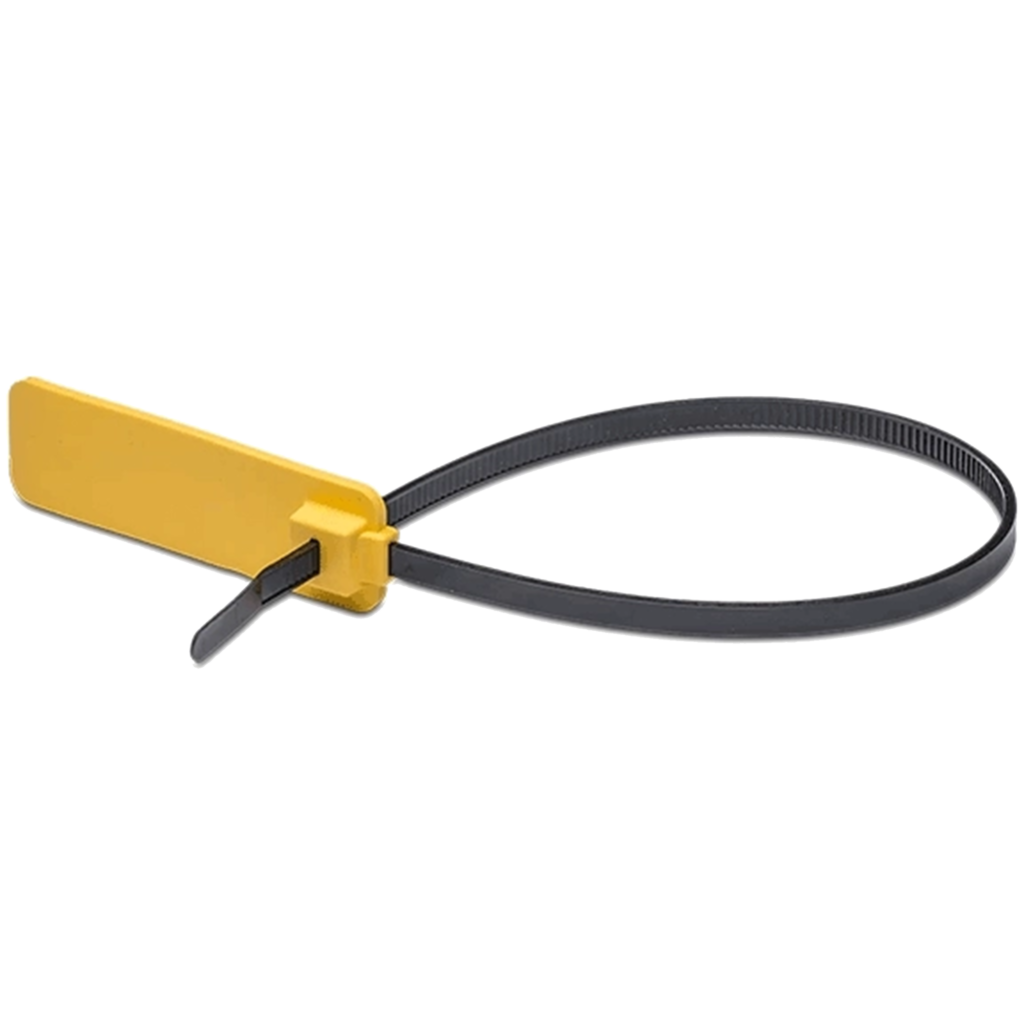

RFID Standard Cable Tie

RFID Standard Cable Ties combine the functionality of a traditional cable tie with advanced RFID technology, enabling secure bundling and reliable tracking in one solution. These ties are ideal for applications that require both physical fastening and digital identification, such as securing cables, tools, equipment, and other critical assets. Designed to withstand challenging environments, RFID cable ties are widely used in logistics, warehousing, manufacturing, and utilities for efficient asset management. Their tamper-evident feature adds an extra layer of security, ensuring the integrity of assets throughout their lifecycle.

Key Features

Integrated Solution: Combines fastening and identification in a single device.

High Security: Tamper-evident design prevents unauthorized removal.

Versatility: Suitable for diverse applications including cables, tools, and movable assets.

Durability: Resistant to chemicals, abrasion, and weather conditions.

Efficient Tracking: Enables automated inventory and audit processes.

Technical Specifications

Operating Frequency: Available in LF, HF, and UHF options for versatile applications

Tag Type: Passive RFID Cable Tie.

Read Range: LF upto 10cm, HF upto 20cm, UHF upto 6m.

Durability: Withstands harsh industrial environments, UV exposure, and extreme temperatures (-40°C to +85°C).

Customization: Color, logo printing, encoding options available.

Technical Specifications

Dimensions and Weight:

Tag: 3.3 × 1.0 × 0.1 in (85 × 25 × 3 mm) Cable tie: 15.0 × 0.3 × 0.1 in (380 × 6 × 2 mm)

Materials:

TPU

Frequency:

13.56 MHz, 860-960 MHz (worldwide)

Protocol:

UHF EPC Class 1 Gen 2, ISO 18000-6C

Chip Type:

MIFARE DESFire EV1, ICODE SLIx, M730, Higgs 4, Higgs 3, UCODE G2iM+ EM | AURA-SENSE

Read distance:

Up to 32.8 ft (10 m)

Data Retention:

Up to 10 Years

Operating Temperature:

-40° to +185° F (-40° to +85° C)

Memory:

Depending on Tag

Affixes To:

Any material (hanging in free air), On metal

Attachment:

Integrated cable tie

Vibration:

IEC 68.2.6 [10 g, 10 to 2000 Hz, 3 axis, 2.5 h]

Places of Application

Cable Management:

Organizing and tagging power and data cables.

Logistics & Supply Chain:

Bundling and identifying goods for shipment.

Asset Identification:

Securing and tracking tools and equipment in industrial settings.

Utility & Telecom:

Managing wires, pipes, and network infrastructure.

Types of Material

Thermoplastic polyurethane (TPU)

Cage UHF Tags are manufactured using thermoplastic polyurethane (TPU), a highly flexible and impact-resistant material known for its resilience under mechanical stress and environmental exposure. TPU construction allows the tags to bend and flex repeatedly without cracking, while also resisting heat, cold, detergents, and industrial washing processes. This ensures long-term performance in demanding laundry and logistics operations.

Types of Detailing on Labels/Tags

Logo Printing

Enhance your brand visibility with custom logo printing available on both the front and back of the labels, ensuring a professional and recognizable design for all your products.

Sequential Numbering

Add unique sequential numbers on the label or release paper for accurate tracking, identification, and enhanced operational efficiency.

Encoding Data

Securely encode essential information directly onto the label, allowing for quick access and accurate tracking of product details, inventory, and more.