RFID Tags for High-Temperature Small Metal Assets

RFID Tags for High-Temperature Small Metal Assets are engineered for reliable identification and tracking in extreme thermal environments where space is limited but performance cannot be compromised. Designed to endure repeated temperature cycles of up to 235°C, these compact tags maintain excellent read performance even when embedded in or mounted on metal surfaces. The Tag combines a small form factor with powerful RFID capability, delivering a read range of up to 4 meters, making it ideal for applications requiring discreet yet dependable tagging. Its robust construction ensures stable operation through high heat, mechanical stress, and challenging industrial conditions, offering consistent traceability throughout demanding production and sterilization processes.

Key Features

High Performance in Small Size: Delivers long read range without compromising compact design.

CExtreme Temperature Resistance: Operates reliably in high-heat environments up to 235°C.

Optimized for Metal: Maintains signal strength and accuracy on metallic surfaces.

Durable Construction: Built for repeated thermal cycling and industrial wear.

Technical Specifications

Operating Frequency: UHF (860–960 MHz).

Tag Type: Passive high-temperature RFID tag for small metal assets.

Read Range: Up to 4 meters.

Durability: Withstands cyclic temperatures up to 235°C and harsh industrial handling.

Customization: Available with custom encoding and asset-specific identification.

Technical Specifications

Dimensions and Weight:

13.1 x 7.8 x 3.1 IC bump +/-0.5 mm 0.52 x 0.31 x 0.12 including IC bump +/-0.02 in

Materials:

PC ABS Blend

Frequency:

866 – 868 MHz (EU) 902 – 928 MHz (US)

Protocol:

EPC Class 1 Gen2v2

Chip Type:

Alien Higgs 3

Read distance:

Up to 4m (13.1 feet)

Data Retention:

Up to 10 Years

Operating Max Temperature:

-20°C to +235°C

Memory:

EPC - 96 bits User - 512 bits Unique TID - 64 bits

Affixes To:

Metal

Attachment:

Film Adhesive (included) for placement only in applications exceeding +85c

Places of Application

Tool Tracking:

Embedded in hand tools, wrenches, and ratchet tools for precise asset identification.

Automotive Industry:

sed in paint, coating, and assembly line processes with extreme heat exposure.

Industrial Production:

Integration within IT assets and machinery at the point of manufacture.

Healthcare:

Suitable for surgical instruments and containers requiring high-temperature sterilization.

Aerospace & Defense:

Ideal for components that undergo frequent high-heat or coating processes.

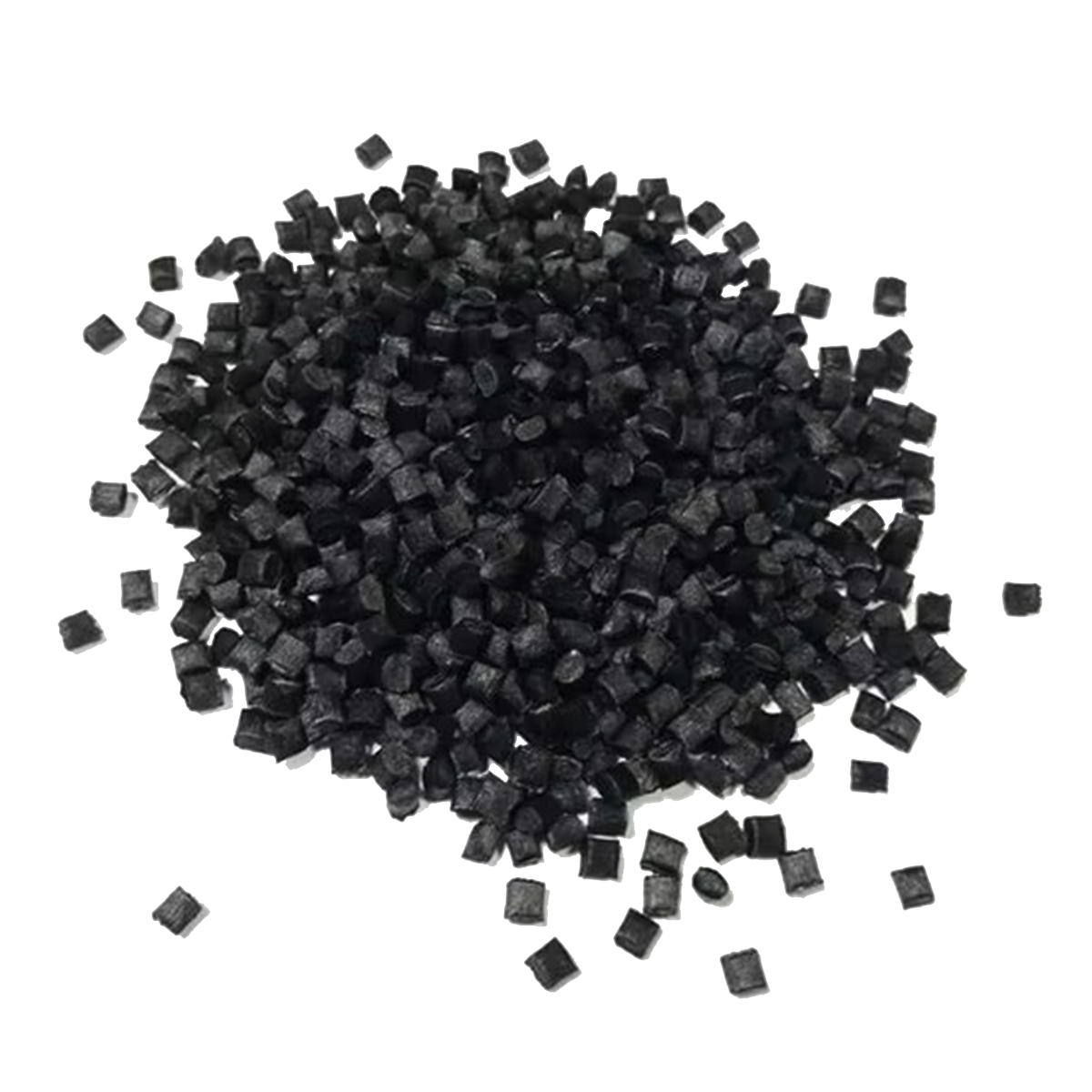

Types of Material

Polymer

These RFID tags are constructed using high-temperature resistant engineering polymers combined with specialized on-metal RF tuning to ensure stable performance in extreme conditions. The rugged outer encapsulation protects the internal chip and antenna from thermal shock, vibration, moisture, and mechanical pressure. This advanced material composition allows the tag to retain structural integrity and read reliability even after repeated exposure to intense heat, making it highly suitable for long-term use on small metal assets in demanding industrial and medical environments.

Types of Detailing on Labels/Tags

Logo Printing

Enhance your brand visibility with custom logo printing available on both the front and back of the labels, ensuring a professional and recognizable design for all your products.

Sequential Numbering

Add unique sequential numbers on the label or release paper for accurate tracking, identification, and enhanced operational efficiency.

Encoding Data

Securely encode essential information directly onto the label, allowing for quick access and accurate tracking of product details, inventory, and more.