Robust RFID Tags for Challenging Environments

Robust RFID Tags passive RFID transponders are engineered for environments where ordinary tags fail. Designed to resist water, chemicals, shock, UV, and extreme temperatures up to 285°F (140°C), these rugged tags perform consistently across demanding industries including manufacturing, logistics, and outdoor asset tracking. With options in Low Frequency (LF), High Frequency (HF/NFC), and Ultrahigh Frequency (RAIN® UHF), IN Tags offer versatile integration across various surfaces — from plastic and glass to wood and metal. Select HF models are certified for use in explosive environments (ATEX/IECEx), and FRAM-based versions provide radiation resistance and write endurance up to 10 billion cycles.

Key Features

Durable & Flame Resistant: UL94-HB rated, withstands impact, chemical exposure, and peak temperatures up to 140°C (285°F).

Versatile Mounting: Can be glued, embedded, or screwed into virtually any surface.

High Capacity & Speed: FRAM options offer up to 8 KB memory and exceptional read/write performance. Food & Radiation Compatible: Suitable for Gamma sterilization and food processing application.

Technical Specifications

Operating Frequency: HF (13.56 MHz) and UHF (860–960 MHz).

Tag Type: Passive, contactless RFID transponders.

Read Range: Up to 3 meters (UHF); short to mid-range (LF/HF)

Durability: Resistant to water, UV, chemicals, and shock; flame-resistant (UL94-HB); operational up to 140°C.

Certifications: Select HF models are ATEX & IECEx certified for explosive environments.

Technical Specifications

Dimensions and Weight:

Ø 20 x3 mm, Ø 30 x 3 mm, Ø 50 x 3 mm 1 to 36g.

Materials:

PPA Polyphthalamide [ISO 1874: PA6T/6I-GF50]

Frequency:

125 kHz (LF), 13.56 MHz (HF/NFC), 865–956 MHz (UHF)

Protocol:

Depending on chip type

Chip Type:

Unique, HITAG S, ICODE SLIX 2, F-Mem, G2IM

Read distance:

Dependent upon reader, environment and application

Data Retention:

Up to 10 Years

Operating Temperature:

-40° to +85° C, Peak 284° F (140° C), 100 h

Memory:

Depending on chip type

Water Resistance:

IP68, IP69K, 176° F (80° C), 100 bar, 30 sec. 16 l/min

Affixes To:

Glass, plastic, wood, metal

Places of Application

Industrial Asset Tracking:

Ideal for tracking tools, machinery, and returnable transport items..

Manufacturing:

Suitable for high-temperature, chemical-heavy, and vibration-prone production environments..

CSupply Chain & Logistics:

Enables reliable identification and status tracking throughout handling and shipping processes.

Hazardous Zones:

Certified HF models support usage in oil & gas, mining, and chemical storage environments.

Medical & Sterile Operations::

FRAM tags withstand Gamma sterilization and are ideal for equipment in cleanrooms.

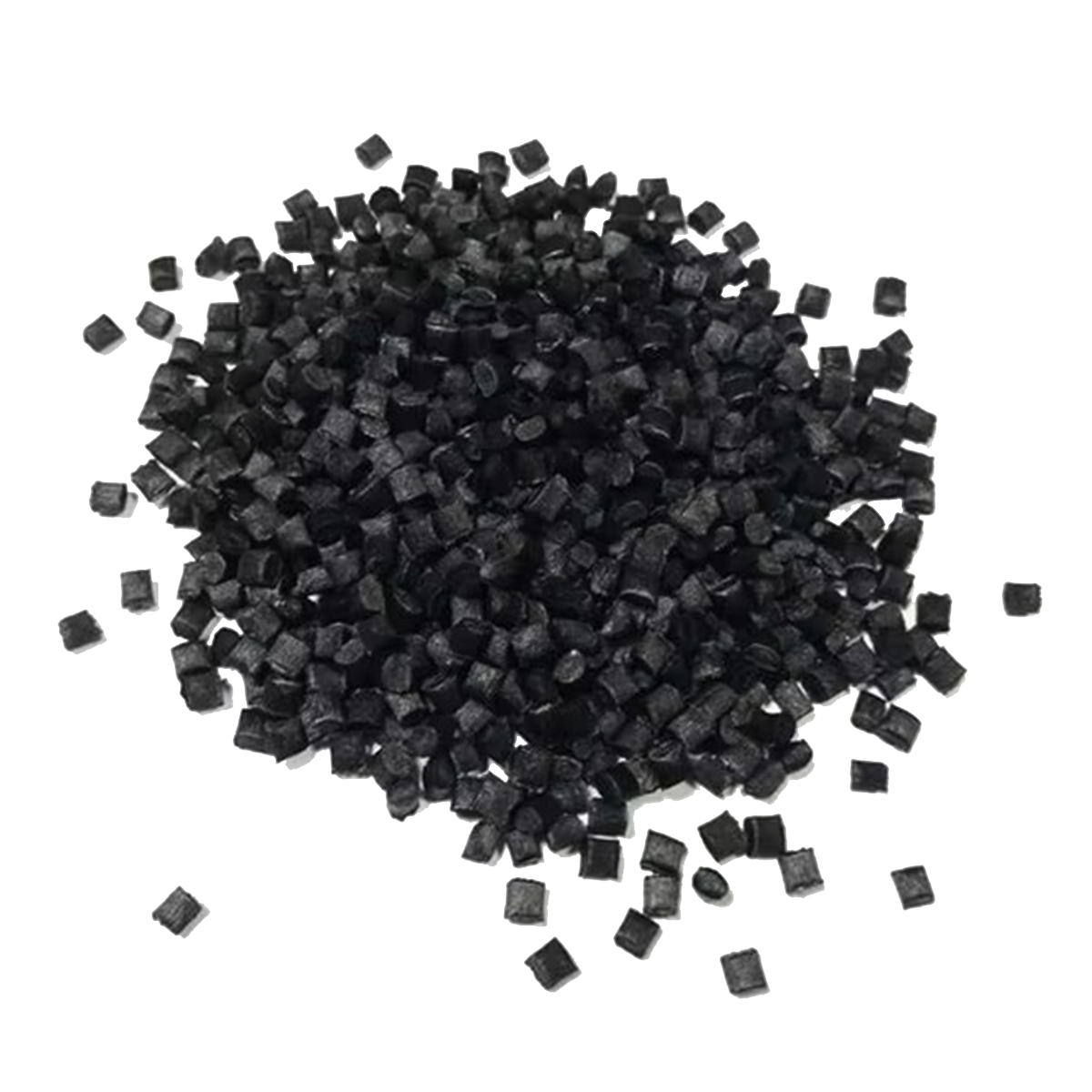

Types of Material

PPA Polyphthalamide [ISO 1874: PA6T/6I-GF50]

These robust RFID tags are housed in high-performance PPA (Polyphthalamide), specifically ISO 1874: PA6T/6I-GF50—a glass-fiber-reinforced thermoplastic known for exceptional mechanical strength, thermal stability, and chemical resistance. This material ensures long-term performance in harsh environments including exposure to fuels, lubricants, extreme temperatures, and physical stress.

Types of Detailing on Labels/Tags

Logo Printing

Enhance your brand visibility with custom logo printing available on both the front and back of the labels, ensuring a professional and recognizable design for all your products.

Sequential Numbering

Add unique sequential numbers on the label or release paper for accurate tracking, identification, and enhanced operational efficiency.

Encoding Data

Securely encode essential information directly onto the label, allowing for quick access and accurate tracking of product details, inventory, and more.