Rugged RFID Bin Tags for Waste Management

Rugged RFID Bin Tags are purpose-built transponders designed to streamline and automate waste collection processes, supporting pay-as-you-throw, recycling incentive programs, and route optimization. Utilizing passive RFID technology, these tags provide accurate data collection without manual input, improving invoicing precision and service accountability in waste management operations. Constructed to withstand demanding outdoor conditions, each Bin Tag features high resistance to water, salt mist, oil, petroleum, and physical impact. They are engineered for easy installation into standard DIN 30745 nests found on most plastic and metal waste bins. These tags offer tamper-resistant designs with a unique four-cavity spanner screw, deterring unauthorized removal in the field. Available in LF, HF, and RAIN® UHF formats, the tags ensure broad compatibility with global RFID standards, providing exceptional read performance whether mounted on plastic or optimized for metal surfaces.

Key Features

Durable & Rugged: High resistance to water, petroleum, salt mist, chemicals, and temperature variations.

Tamper-Resistant: Equipped with a unique four-cavity spanner screw drive to prevent unauthorized removal.

Easy Installation: Designed to fit standard DIN 30745 bin nests for seamless integration and retrofitting. Reliable Performance: Ensures consistent readability even in rough environments and on both plastic and metal bins.

Technical Specifications

Operating Frequency: 125 kHz (LF), 13.56 MHz (HF/NFC), 865–956 MHz (UHF).

Tag Type: Passive contactless transponders.

Read Range: Varies by frequency and reader, optimized for field use.

Durability: Resistant to water, salt, oil, UV, impact, and temperature from –40°C to +85°C.

Customization: Available with various chip types, dimensions, and memory configuration.

Technical Specifications

Dimensions and Weight:

1.18 x 0.59 in, thread 1.12 in (Ø 30 x 15 mm, thread Ø 28.5 mm) (Customization Available)

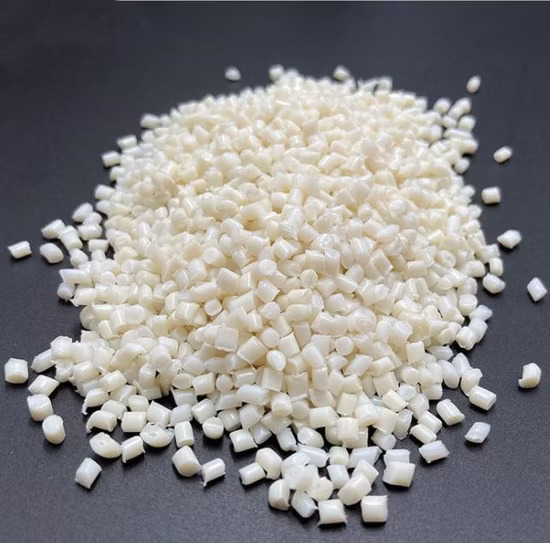

Materials:

PA6, potting PUR

Frequency:

125 kHz (LF), 13.56 MHz (HF/NFC), 865–956 MHz (UHF)

Protocol:

ISO/IEC 18000-6C; EPC Global Class 1 Gen 2

Chip Type:

Unique, FDX-B, BDE, HDX, BDE ICODE, SLIX M730

Read distance:

Dependent upon reader, 20 ft (6 m)

Data Retention:

Up to 10 Years

Operating Temperature:

-40° to +185° F (-40° to +85° C)

Memory:

96 bits, 128 bits

Attachment:

Screw-in

Places of Application

Waste Management & RTIs:

Reliable ID for bins, crates, and reusable containers

Types of Material

PA6 with PUR potting

PA6 (Polyamide 6), commonly known as Nylon 6, is a strong, durable thermoplastic known for its excellent mechanical properties, wear resistance, and toughness. It performs well under high stress and in harsh environments, making it ideal for industrial RFID tag housings. PUR (Polyurethane) potting is used to encapsulate and protect the internal components of RFID tags from moisture, dust, shock, and vibration. This combination ensures the tag remains operational in extreme conditions such as exposure to chemicals, temperature fluctuations, and physical impact, making PA6 with PUR potting a reliable choice for rugged and outdoor RFID applications like waste management, logistics, and asset tracking.

Types of Detailing on Labels/Tags

Logo Printing

Enhance your brand visibility with custom logo printing available on both the front and back of the labels, ensuring a professional and recognizable design for all your products.

Sequential Numbering

Add unique sequential numbers on the label or release paper for accurate tracking, identification, and enhanced operational efficiency.

Encoding Data

Securely encode essential information directly onto the label, allowing for quick access and accurate tracking of product details, inventory, and more.